Coding and marking in the coffee industry are essential aspects of product packaging, traceability, and brand management. These processes involve applying identifying information to coffee packaging, which can include a wide range of details such as batch numbers, expiration dates, manufacturing dates, barcodes, and QR codes. Here’s an overview of their importance and applications:

1. Traceability

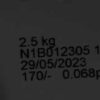

- Batch Numbers and Dates: Coding systems help in tracing the product back to its production details. For instance, if there’s a recall or quality issue, companies can identify which batches are affected.

- Source Information: Especially important for specialty coffees, codes can detail the origin of the beans, including the farm, region, or country, enhancing consumer trust and product value.

2. Regulatory Compliance

- Governments and regulatory bodies often require products, including coffee, to have specific information on their packaging. This includes expiration dates, manufacturing dates, and sometimes nutritional information or allergen warnings.

3. Brand Differentiation and Marketing

- QR Codes: These can be scanned by smartphones, directing consumers to websites for more information about the product, promotions, or the brand story. It’s a way to engage consumers directly and enhance the brand experience.

- Custom Markings: Creative and unique codes or markings can differentiate a brand on crowded shelves, making products more recognizable to consumers.

4. Operational Efficiency

- Automated coding and marking systems streamline the packaging process, ensuring consistency and accuracy in the information provided on each package. It helps in inventory management and reduces errors in packaging.

5. Sustainability and Ethical Information

- Codes can also convey information about the coffee’s sustainability credentials, such as organic or fair trade certifications, appealing to consumers who value ethical consumption.

Technologies Used

- Inkjet Printers: Common for printing dates and batch numbers due to their versatility and ability to print on different materials.

- Laser Marking: Offers durability and resistance to fading, which is beneficial for products that may be exposed to moisture or oils.

- Thermal Transfer: Ideal for high-resolution barcodes and labels that require long-lasting print quality.

- Labeling Machines: For applying pre-printed labels with barcodes, QR codes, and detailed product information.

Inkjet Printers in the Coffee Industry

Inkjet printers are widely appreciated in the coffee industry for their versatility and efficiency in coding and marking packaging. These printers are capable of printing on a variety of packaging materials commonly used for coffee, such as foil bags, paper labels, and plastic containers. They offer fast, non-contact printing, which means they can print codes and markings on moving products along a production line without needing to touch the items physically. This reduces the risk of damaging the packaging and allows for high-speed production processes.

Advantages of Inkjet Printers

- Flexibility: Inkjet printers can easily adjust to print a wide range of information, from batch numbers and expiration dates to logos and barcodes. This flexibility is crucial for coffee producers who need to change codes frequently or offer limited editions with specific markings.

- High-Speed Printing: They can keep up with fast-moving production lines, ensuring that every product is marked without slowing down operations. This is essential for meeting high demand and reducing bottlenecks in the packaging process.

- Ease of Integration: Inkjet printing systems can be easily integrated into existing production lines, requiring minimal modifications. This ease of integration helps coffee producers adopt or upgrade their coding and marking systems without significant disruptions.

Thermal Inkjet Printers: Enhanced Advantages

Thermal inkjet technology offers additional benefits for the coffee industry. These printers use heat to propel ink onto the substrate, creating high-resolution, durable markings that are resistant to smudging and fading. This makes them ideal for coffee packaging, which may be exposed to various environmental conditions such as moisture and heat.

- High-Resolution Printing: Thermal inkjet printers produce sharp, clear codes and images, enhancing readability and scanability of barcodes and QR codes. This precision is vital for traceability and retail scanning.

- Low Maintenance: With fewer moving parts and no need for compressed air or external pumps, thermal inkjet printers are generally more reliable and require less maintenance than other types of coding equipment. This reduces downtime and operational costs.

- Environmentally Friendly: Thermal inkjet printers use cartridges that are easy to replace and recycle, reducing waste. They also typically have a lower solvent usage, making them a more environmentally friendly option for coffee producers concerned with sustainability.

Conclusion

Inkjet and thermal inkjet printers offer a compelling combination of speed, flexibility, and quality for coding and marking in the coffee industry. Their ability to print on various substrates with high resolution and minimal maintenance makes them an advantageous choice for coffee producers looking to enhance their packaging efficiency, compliance, and brand visibility.

Recent Comments